What is meant by soldering in electronics? Simply, it is a process to join various electronics components on a dedicated board called the printed circuit board (PCB).

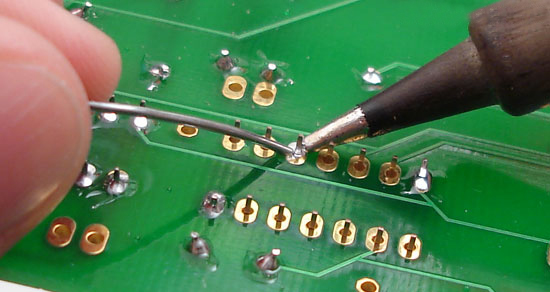

The process of soldering in electronics starts with a hot soldering iron. We put this hot iron on the point where we want to make a connection. The point can be a solo terminal of a component through the hole of the PCB. It can be a common node of two circuit branches.

The hot iron melts down the soldering wire and a permanent connection is made on the point of our interest. This process of melting down the soldering wire and making a connection is called soldering. This process continues for all the connections of the circuit, and in the end, we have a really nice finished PCB board.

Hi, I am Abbas. If the above short introduction got your attention. Then I am sure you will find the rest of this article useful.

Because in the rest of this article, I talk in great detail about what we mean by soldering, why it is so important, what are the tools that can help us do the soldering, and much more.

I am not perfect, nor this article is going to be. This is just my limited knowledge try to help you somehow.

I hope you will enjoy it.

What is meant by soldering in electronics?

Electronics is all about studying the behaviors of various semiconductor devices and how to put them together to create solutions for various problems.

By putting together various electronics components, I mean making a proper working electronics circuit. You can achieve this task by connecting them in many ways.

Early in the days, people used to make circuits in the following way.

Those circuits were bulky and cannot be commercialized at a reasonable price tag. That is why early electronics product was so expensive.

But as we progress in time, new technology were developed. Printed circuit board technology is one of the early advancements in the field of electronics. This has completely changed the dynamics of circuit making.

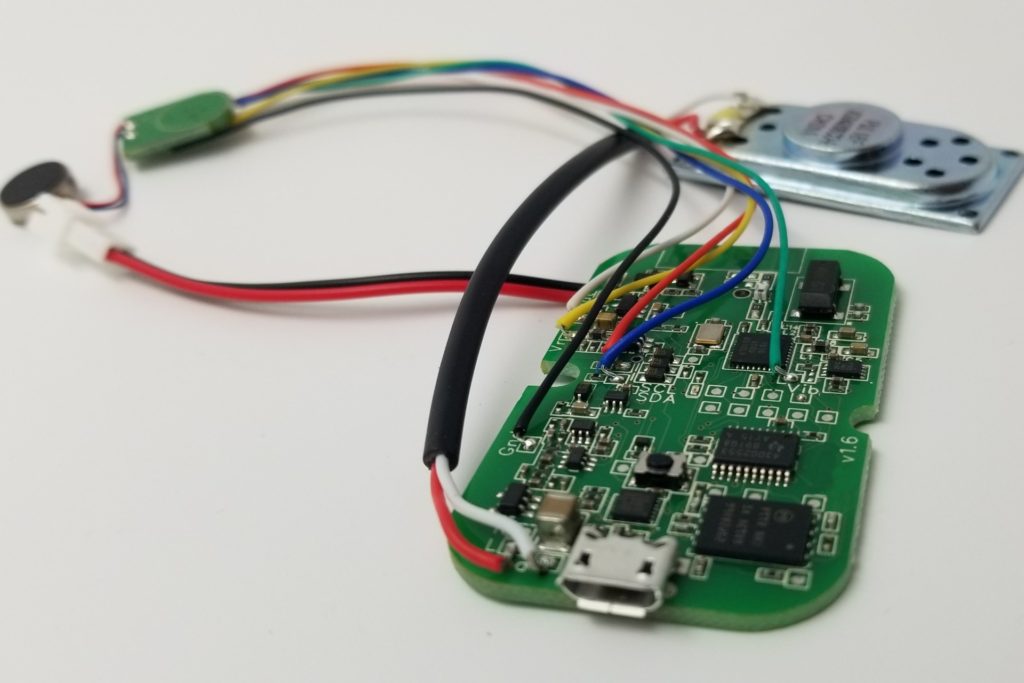

Nowadays, circuits look like the below. I am sure you have seen them somewhere.

You can clearly see the difference and advancement. You can commercialize the latter one at a reasonable cost.

Now, to work with these PCB circuits you need to join all the various electronics components together as per the requirement of the circuit design. And with this, there is a need for an easy and reliable process.

This reliable process of joining various electronics components on PCB is called soldering.

It is not necessary you will always do soldering on PCB. Sometimes we also do soldering on Veroboards as well. It depends on what project we are working on.

We also do soldering for circuit repair work as well. So, do not generalize soldering to just PCB board. Remember it as, the process of joining various electronics components and devices together in the most effective way possible.

Let’s try to understand it on a more deep level.

For which we first need to understand what is a PCB and Veroboard.

Printed Circuit Boards (PCBs) & Veroboard

Starting from Verobaord first as I think it is the easiest one to understand.

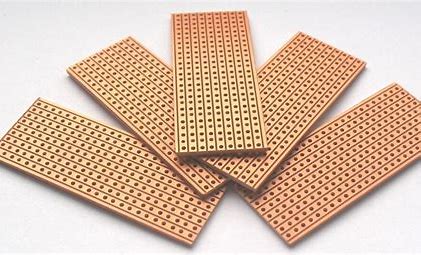

A Veroboard is a fundamental tool when it comes to soldering circuit prototyping. It is mostly used by students and beginner level electronics enthusiasts.

As you can see, it has copper traces and comes in various shapes and sizes. It has rows and columns of holes. We put our components in these holes.

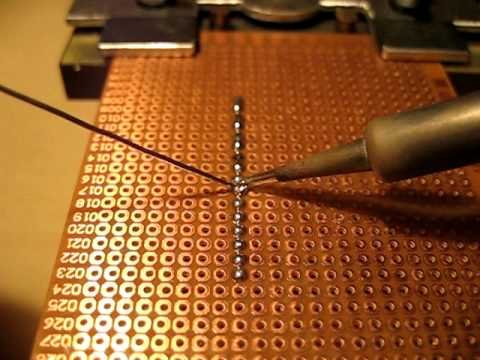

The terminals of the component go through holes. Then we put soldering wire and soldering hot iron. The hot iron melts down the soldering wires and a connection is made.

Other than size, veroboards have two special categories:

- Shorted copper strips board

- Open copper strips board

These types of veroboards has own respective usage and application. We work with any of them depending on what are the requirements of the circuit. But in my experience, shorted strips boards are easy to work with as the compared to the open one.

With Veroboard you have to connect all the components according to the schematic of your circuit. You have to make the wires traces (by using external wires or by removing the copper traces from the given board) yourself correctly. If you make a mistake while making a connection, it is very hard to undo that in verobaords.

Now if talk about PCB soldering then it is a little different. PCB boards are those green boards which you can find in almost every electronics device.

In PCB all the wire connection are made by machines. We just need to solder our components correctly.

PCB soldering is the final goal of any electronics product. As it can be done by machines and there is little chance for error.

So to summarize what is meant by soldering in electronics, I can say: It is the process of joining various electronics components according the circuit design by the use of soldering stations and various other soldering accessories.

Soldering is not limited always making new circuit boards. We also do soldering for circuit repair as well.

Advantages of soldering

I guess you have got some idea by now that soldering is really important in electronics. It helps us make compact circuit boards with low cost.

Let’s see some advantages of soldering in the following:

Compact board size

Imagine a bulky and full of wires circuit. No one will ever buy that product with that circuit board. It will be noise and easy to get damaged.

The compact size board that we see in these modern day products is possible because of advancement in PCB and soldering techniques.

With the compact size there comes the advantage of low chances of circuit damages. As during the soldering components are joint together strongly, and the chances of breaking these joints are very low.

User friendly

Soldering in electronics is very user friendly. I am sure if you practice for a month you can do pretty decent soldering at the end. There is complicated stuff involved. In fact, it is fun to DIY soldering.

Of course at professional level you have to really careful but at the beginning it is very easy to get started.

Automation for batch production

With PCB and soldering it is only possible to automate the whole process on batch level production.

We need automation to cope with the rapid demand of electronics products. And it is possible only that we have automated soldering mechanism in our industry.

Low cost

When we automate things, they become low cost as we eliminate a lot of expenses. Similarly, with automatic soldering and PCB the electronics products are becoming low prices.

Circuit repair

The other useful application of soldering is circuit repair. By circuit repair I mean to replace a bad component with a new working component. We use soldering to repair the old circuit with minimum cost thus saving us useful resources.

Soldering tools list

In electronics, soldering is the most amazing job to do. But at the same time, if you lack quality tools for it, you may end up with a bad finished board. And we don’t want that in any case.

Without soldering tools, it is nearly impossible to have a fine looking board. In case you compromise on any of these tools (which is fine if you are DIY or just a complete beginner) then your circuit board may have added noise, some extra radiation, and may fail regulation rules for batch manufacturing.

Following are the must have tools list for soldering.

- Soldering iron

- Soldering station

- Desoldering station

- Hot air rework

- Smoke and fume extractor

- Pre-heater for soldering PCB

- Helping stands

- Magnification microscope

Above are the main tools needed to solder a circuit board. Besides these tools, we should have the following soldering accessories as well.

- Firm stand

- Solder sucker

- Flux

- Soldering mat

- Tweezer

- Wire cutter and pliers

- Desoldering wick

- Solder tape

- Brass cleaner

Above are just the list. To make a professional level finished board we need to have proper tools for soldering circuit boards. Following is the article where I walk you in detail about these tools. I hope you will enjoy it too.

Conclusion

In electronics, we design circuits. Our end goal is to commercialize those circuits at the minimum cost possible.

This process of designing a circuit to the final manufacturing stages has many steps. One of the steps is called soldering.

With this there comes the question of what is meant by soldering in electronics anyway.

The answer to this question is simple. Soldering in electronics is a process of joining various electronics components on a specific board (Veroboard, or printed circuit board) by using soldering stations, wires, and various other soldering accessories.

In soldering, we put the hot soldering iron on the soldering wire. The wire melts down, and a connection is made. This connection can be between two components or between any nodes of the circuit as per the requirement of the circuit schematic design.

Soldering helps us to have compact size boards at a very low cost. We also use soldering for circuit repair activities as well.

To do the proper soldering there are some dedicated soldering tools that one must have in order to make a professional level circuit board.

So that is it. That I know about soldering in electronics. I hope this article has helped you somehow, and you enjoyed it.

Thank you and have grateful life.

Other useful posts:

- Do I need helping hands for soldering? (Answer)

- Major differences between Breadboard and Veroboard

- 7 Best soldering fume extractor

- Key questions about soldering fume extraction

- 7 Best Soldering Irons for Electronics