In electronics, soldering is the most amazing job to do. But at the same time, if you lack quality tools for it, you may end up with a bad finished board. And we don’t want that in any case.

So in this article, I will walk you through some basic tools needed to solder a circuit board in the most professional way possible. These tools are a good quality soldering station (not a solo iron), decent holding hands, flux, wax, soldering fume extractor, and much more.

Without these tools, it is nearly impossible to have a fine looking board. In case you compromise on any of these tools (which is fine if you are DIY or just a complete beginner) then your circuit board may have added noise, some extra radiation, and may fail regulation rules for batch manufacturing.

Hay! I am Abbas. If you find the above exciting then I am sure you will find the rest of this article enjoyable.

In the rest of the article, I will talk in more detail about the above mentioned tools, will share tips about soldering, and much more.

I am not perfect nor this article is going to be. This is just my limited knowledge try to help you somehow.

I hope you will enjoy it.

Tools needed to solder a circuit board

We solder a circuit for two main reasons. Either we are repairing it or we are prototyping it. The prototype includes DIYs, small projects, making a circuit from the given schematic, or making a circuit on a PCB.

In any of the cases, the following are the tools needed to solder a circuit board.

Solder iron (solo pencil type)

As you are reading this article it means you may be a beginner person getting into the world of soldering. So let me explain everything in a simple way.

Solder iron is the first tool needed to solder a circuit board. It looks like the below one:

You power up this tool and its tip gets heated. You put this hot tip on the soldering wire. The wire melts down and makes a joint on the circuit board.

This process of making a connection is called soldering. The tool you use for it is called the soldering iron. The wire which melts down and makes the connection on board is called soldering wire.

The tip of soldering iron comes in different shapes which are intended for application specific requirements. But the most used one in electronics is the pencil type. The pencil type looks like a pencil tip that is why it is called so.

Now, you will find a bunch of soldering iron on the market. Knowing which one to choose depends on the Wattage rating. The higher this rating value the better the soldering iron.

Also, the iron must be ESD safe meaning it should not harm the component you are soldering. For starters, you may check this soldering iron Weller Soldering Iron (Amazon link).

Soldering Station

In electronics circuit board soldering we often require different temperature values for specific components. If you have a solo soldering iron as we saw above then it will fail to work.

Because a solo iron has a fixed temperature value. Also, there are others missing with a solo iron. Such as a solid stand (which you will definitely have one. Because where you will put the hot iron anyway?).

To tackle these issues there is a tool called the soldering station. It has all the required things for a good soldering process.

In the above picture, the black thing is the stand where you put the hot iron when you are not working. The yellow thing is a station from where you can change the temperature of the attached soldering iron according to the circuit requirements.

Following is the post that will walk you through soldering in great detail. Like what parameters to look for when buying one and what are some best soldering stations out there to look at.

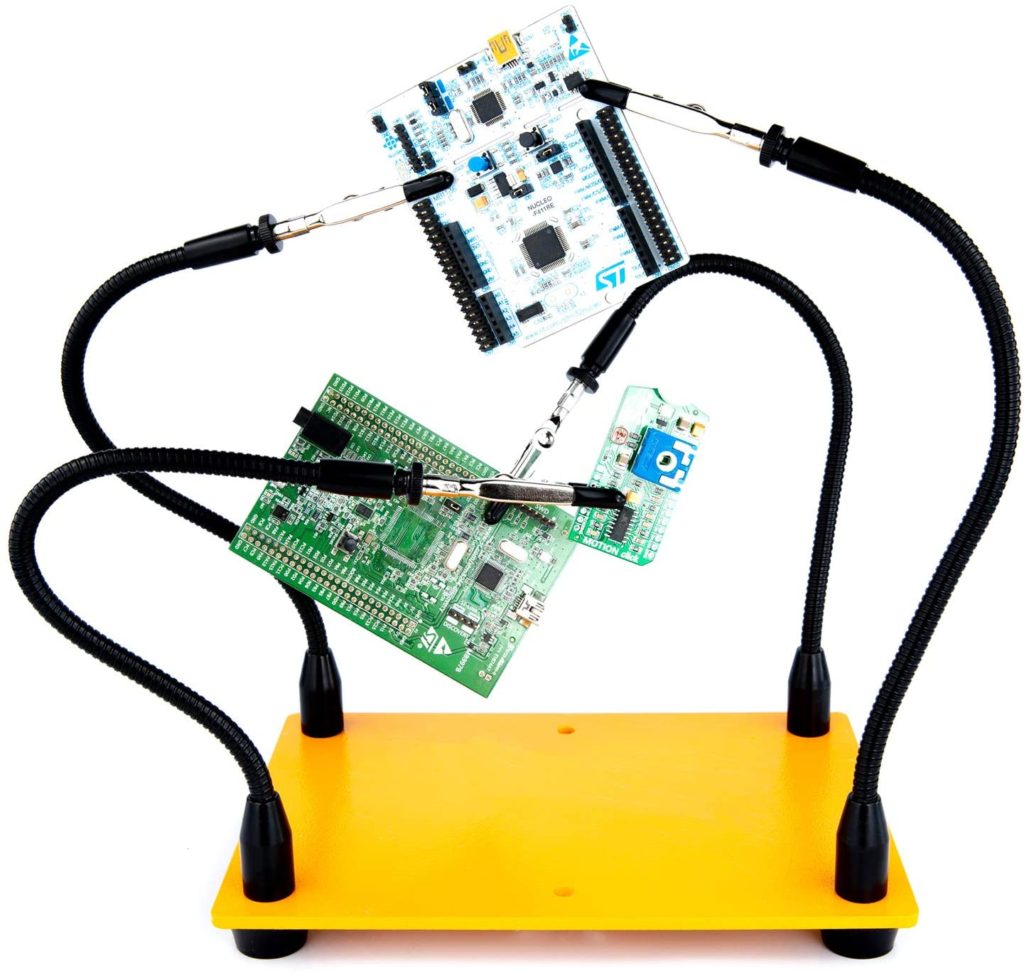

Circuit holding hands

We saw a soldering station now we need a tool to hold our circuit properly, so we can solder it. As a beginner, you may not require it that much if you have to work on one or two circuits just for testing.

But if you are planning to solder a lot of circuits then you must have a decent circuit holding hands. Without these tools, you will not make a really fine finished circuit.

See these hands are pretty good looking as well as do the hardest job as well. You can attach a magnifying scope to it as well. Also, you can attach a light LED as well to see things or tiny components much clear.

Now there is a variety of helping hands there. Choosing the best one really depends on a few things which I have explained in the following dedicated post.

Soldering fume extractor unit

With soldering there comes the soldering smoke. This is the smoke generated when you make a connection on a circuit board.

If you are working in a close environment and soldering is what you want to do for a long time. Then you must have a decent soldering smoke extraction unit. As this smoke is not good for the lungs if exposed for a really long period of time.

A soldering fume extractor absorbs the harmful smoke, filters it, removes the harmful components from it, and gives you fresh air to breathe.

This is a very useful tool a lab must have. But if you work in a large space then maybe just a decent soldering fan would be enough for you.

I never strongly recommend compromising on your health. Health is a rare gift you should protect it. So, if you want to solder first get yourself a decent fume extractor.

Hot air rework

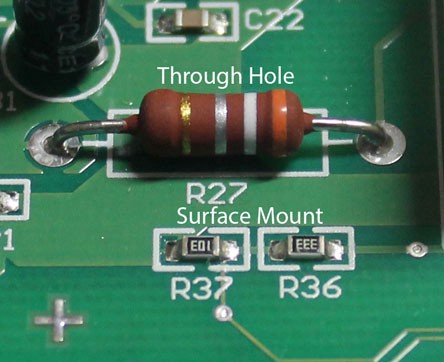

Electronics components are of two types one is called the through hole components and the other is the surface mount devices (SMDs).

We solder through hole components by using a soldering station as we discussed above. But when it comes to SMDs soldering iron or station fails, we need an extra device to solder such components.

Such a device to solder SMDs is called the hot air rework. It blows the hot air for melting the soldering wire and that is why it is named hot air rework.

The black thing on the very left is the shirt air blowing gun. It blows hot air. You know, SMDs are small components and this gun melts the soldering wires across the small terminals of any SMDs. Thus making a perfect connection with high level neatness.

If you are working with a lot of repairs then a cost-effective idea is to buy a combo of both soldering station and hot air rework. See for example this model, YIHUA 862BD (Amazon link).

Desoldering station and gun

The other part of soldering is desoldering. Soldering is to permanently join the two branches on a circuit board while desoldering is to open them.

There is a need for desoldering in the following situations:

- You want to replace a bad component from the circuit board

- You make a mistake while soldering

A desoldering station is like a soldering station, but it has a gun that melts down the soldering wire and sucks it inside it. Thus giving you a clean open connection.

Now there are many desoldering stations out there. If you are a newbie and don’t know which technically accept to look for in picking a quality desoldering station, then the following post might be helpful for you.

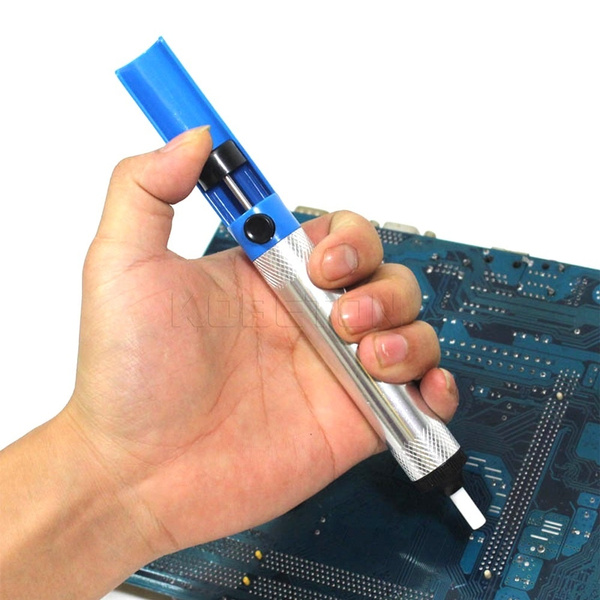

Solder Sucker

This tool is basically a fundamental level desoldering station. We use this tool to suck the soldering wire from the circuit connection.

The main difference between a sucker and the desoldering station is, that for the sucker you have to melt down the soldering wire with other hot solder iron. While in the desoldering station the gun has all this functionality inbuilt.

Sucker is geared towards small tasks. Like if you are a beginner or if you occasionally desolder two or three components.

In my opinion, you should not go for it if you are working full time on repair projects. Yes, you should have one, like this one Tabiger solder sucker (Amazon link), in your lab as it is not that expensive and can help in most situations.

Soldering microscope

As we are getting more technologically advanced. You may have noticed that the size of electronics components is decreasing day by day. Which is really nice thing.

But this shrinking of component size has made it challenging to meet the criteria of professional level soldering. You just cannot go there in the lab and make a soldering connection like that. These connections must be clean and neat.

So, to work with these tiny components we need a dedicated tool. Such a tool is called a soldering microscope. It zooms in on the components so that we can make a proper connection.

In simple, soldering microscopes are one of the basic needs of professional soldering. Especially if you have some SMDs to work with. The beauty is you can inspect and see all the detail of any electronics circuit on its big display screen.

Now, choosing the best digital microscope for soldering can be confusing for the first time. You need to have some basic understanding of what to look for in a good scope, which brands to select, and perhaps a lot of other questions. The following post will help you with all of these questions.

Flux

Flux is basically a chemical which I don’t know which chemical. But it is a chemical that removes the oxide layer from the metal surface of the PCB. Thus helping us to have more strong and clean connections.

You can make the connections without it in some cases. But it is always good to use flux for your soldering. It makes the connection strong so that it doesn’t break easily.

Instead of using this, you can also use a solder flux pen (Amazon link) which is easier to use than this chemical flux.

Bras tip cleaner

As the name suggests it is the soldering iron tip cleaner. We need this tool as when are done with soldering the tip must be cleaned for the next time usage.

This increase the life span of our tips. Also, it helps us to have better and more clean connections.

Tweezers

In soldering, you are working with a hot iron which can harm you seriously if care is not taken. You are not supposed to hold the component in one hand and solder it with another hand, especially if you are soldering tiny components.

For such a task you must have a tweezer to hold the component you are soldering on the circuit board. One important thing to keep in mind, these tweezers must be ESD safe so that they don’t harm or damage the components.

Mat

It is like a specific area where we do the soldering work. It resists the heat and also keeps our tool organized.

This is one of the fine accessories for effective soldering. I don’t know but it makes soldering fun. A mat is made of high quality materials that not only can resist heat at 932 °F (500℃) and protect your workbench but is also easy to clean and store.

Must have for a beginner person

You will hear from a lot of people to start with a solo iron. But I really don’t think that is a good idea. I think one should always start with a proper soldering station so that he can understand the soldering process more professionally and effectively.

Also, a soldering station comes with all the basic accessories such as a stand, tip cleaner, soldering wires, flux, and much more. This means you don’t have to buy these accessories individually.

If you ask me, I will recommend starting with the Hakko soldering station (Amazon link). It is very uniquely designed, used by thousands of professionals, and has a very decent price tag.

Conclusion

Soldering plays a crucial role in making circuits. We do soldering for either repair work or for making a PCB prototype of a given circuit.

To make a professional level finished board we need to have proper tools for soldering circuit boards.

Following are the tools needed to solder a circuit board:

- Soldering iron

- Soldering station

- Desoldering station

- Hot air rework

- Smoke and fume extractor

- Pre-heater for soldering PCB

- Helping stands

- Magnification microscope

Above are the main tools needed to solder a circuit board. Besides these tools, we should have the following soldering accessories as well.

- Firm stand

- Solder sucker

- Flux

- Soldering mat

- Tweezer

- Wire cutter and pliers

- Desoldering wick

- Solder tape

- Brass cleaner

With this, we have come to the final stage of this article. That is all I have for you to share. I hope you enjoyed it.

Thank you so much and have a grateful life.

Other useful posts:

- 20 Best soldering stations [beginners to professionals]

- 11 Best desoldering stations and guns to buy

- What is Circuit Prototyping & why it is so important

- 7 Best Soldering practice kits (For beginners)

- 7 Best Electronic Components Organizers (Quality)